| Code |

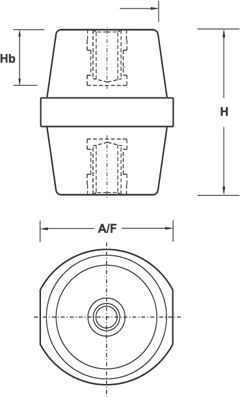

Height

H mm |

Insert |

Dimensions |

Nominal voltage

(AC/DC) |

| |

|

|

A/F mm |

R mm |

Hb mm |

|

| D420 |

20 |

M4 |

18 |

14 |

5 |

800/1100 |

| D620 |

20 |

M6 |

18 |

14.5 |

5 |

800/1100 |

| D625 |

25 |

M6 |

21 |

16 |

7 |

1000/1400 |

| D630 |

30 |

M6 |

33 |

25 |

9 |

1200/1600 |

| D830 |

30 |

M8 |

33 |

26 |

9 |

1200/1600 |

| D635 |

35 |

M6 |

32 |

26 |

12 |

1400/1900 |

| D835 |

35 |

M8 |

32 |

26 |

12 |

1400/1900 |

| D1035 |

35 |

M10 |

32 |

26 |

12 |

1400/1900 |

| D840 |

40 |

M8 |

39 |

30 |

12 |

1600/2200 |

| D1040 |

40 |

M10 |

39 |

31 |

12 |

1600/2200 |

| D845 |

45 |

M8 |

40 |

31 |

12 |

1800/2500 |

| D1045 |

45 |

M10 |

41 |

32 |

12 |

1800/2500 |

| D1245 |

45 |

M12 |

41 |

32 |

12 |

1800/2500 |

| D1050 |

50 |

M10 |

48 |

35 |

17 |

2000/2800 |

| D1250 |

50 |

M12 |

48 |

35 |

17 |

2000/2800 |

| D851E |

51 |

M8 |

35 |

27 |

17 |

2040/2800 |

| D1051E |

51 |

M10 |

35 |

27 |

17 |

2040/2800 |

| D1060 |

60 |

M10 |

52 |

37 |

17 |

2400/3300 |

| D1260 |

60 |

M12 |

52 |

37 |

17 |

2400/3300 |

| D865 |

65 |

M8 |

55 |

41 |

22 |

2600/3600 |

| D1065 |

65 |

M10 |

55 |

41 |

22 |

2600/3600 |

| D1265 |

65 |

M12 |

55 |

41 |

22 |

2600/3600 |

| D1070 |

70 |

M10 |

55 |

42 |

22 |

2800/3900 |

| D1270 |

70 |

M12 |

55 |

42 |

22 |

2800/3900 |

| D1075 |

75 |

M10 |

55 |

42 |

22 |

3000/4200 |

| D1275 |

75 |

M12 |

55 |

42 |

22 |

3000/4200 |

| D1076E |

76 |

M10 |

50 |

34 |

22 |

3000/4200 |

| D1276E |

76 |

M12 |

54 |

42 |

22 |

3000/2400 |

Material: DMC (Dough Moulding Compound)

Insert: Steel (zinc passivated)

Working temperature: (-) 40˚C to 135˚C

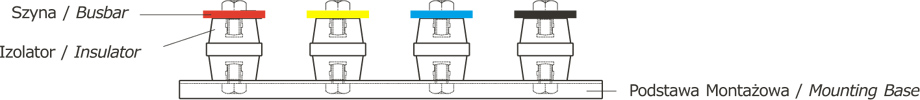

Mounting Arrangement:

| Tightening Torque |

| D 835, D 845, D 851E |

150 – 275 kg cm |

| D 1045 |

250 – 300 kg cm |

| D 1060, D 1075, D 1076E |

375 – 550 kg cm |

Support to Support Distance: Should not be more than 250 mm